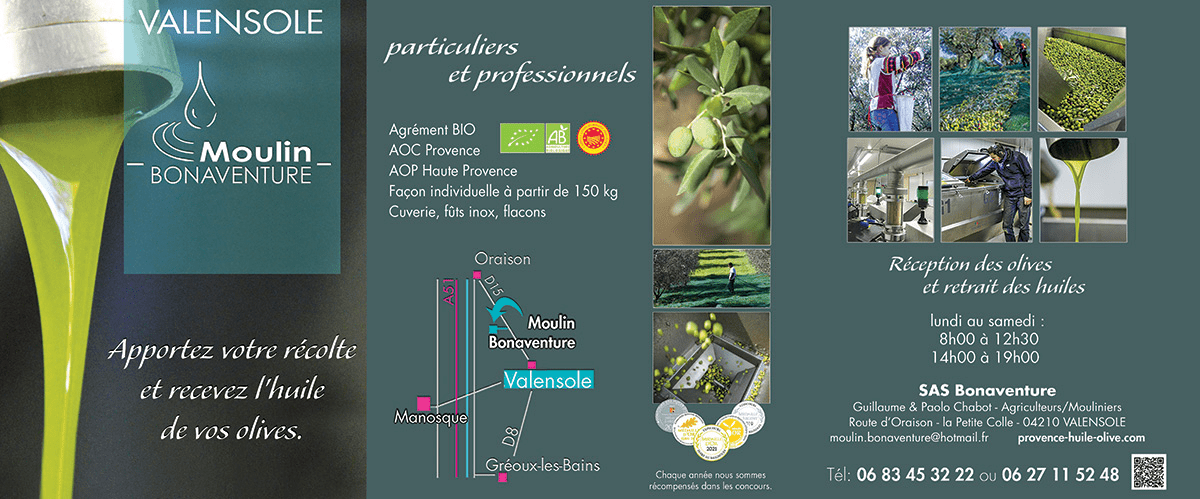

To the producers of olives to the people who have olive trees in their backyard. (even in small quantities)

- from 150Kg of olives you have you own olive oil.

- For a lot bigger than 150Kg, you can make an appointment (phone: 06 83 45 32 22 or 04 92 74 81 92).

- We are organic and PDO authorized.

- We can lend crates, vat or containers.

- We receive the olives from 9 a.m.

From November to January, olives are harvested by hand. We make them fall on some net thanks to a rake or an electric comb. Then, they are transported to our mill where we remove all the remaining leafs. Olives will be transformed to oil from maximum 12 hours after the harvest in order to keep their freshness, to preserve their aroma and to avoid all kind of oxydation.

The transformation into oil begins with the cleaning of the olive fruits and the grinding.

The grinding is extremely important as it is the unique moment where the olives are in contact with oxygen to initiate the enzyme process that will free the oil from the cells. The stone of the fruit is crushed with the fruit itself and the paste we obtain will be transferred into the secon dstep of the process which is the mixer.

In the mixer, the paste we previously obtained is heated to 25 °C during 20 minutes in a controlled atmosphere. The aim of the mixer is to free the oil from the fruit by breaking the vacuole of the cell (the little cavity that contains the oil in the cell).

At the end of the mixing process, the oil begins to come to the surface of the tray and the paste is transferred to a decant machine. Technically, the decant machine is a horizontal centrifuge that allow us to separate the oil by gravity. Oil being lighter than water and the pulp, it can be found on the center of the centrifuge.

The work of the mill worker is to set all the different parameters of the machine to retrieve the purer oil at the core of the machine. A pure fruit juice. The remaining paste is brought to a machine where the stones (a very good combustible) are separated from the paste which will be used as a fertilizer in our fields. Similar to the great wines, we avoid to rush the oil in the pump or the filters of the machine. The oil is simply put to decant and the transfers from vat to vat are simply done by gravity. The olive oil is then stocked in stainless steel vat with a specific cap to avoid any contact with oxygen. The oil is finally put in the bottle gradually, following our needs. Thus we are able to guaranty a total traceability, from the tree to the bottle, from the fruit to your plate.